GLASS BOTTLE AND JAR PLANTS!

The Option to Close Your Production Loop is Finally Here!

The Figures Don’t Lie

Things to think about:

Environmental laws are getting tougher in many states such as California, Colorado, Connecticut, Delaware, Hawaii, Maine, New Jersey, New York, Oregon, Rhode Island, Vermont and Washington. State – wide bans in Colorado and Rhode Island just went into effect at the start of 2024.

Make a Positive Change

Letter from the Inventor:

Consumers continue to grow increasingly aware that when we throw something away, “away” is just someone else’s “here.” We know our floss, ketchup packets, and sandwich bags whirl in the Great Pacific Garbage Patch, and the ocean is soon to contain more plastic than fish.

FEAR. That’s what many feel about the future, and there is no greater motivator for behavior change. That’s why closed systems are the future of business. Closing the loop simply means modeling your business so that every item (packaging or otherwise) going out has a way to come back to be shared, repaired, reused, or recycled. Businesses that don’t concern themselves with the end result of packaging and waste will soon face the firing squad of public opinion.

More and more people, especially those in the younger generations, are waking up to the consequences of convenience. Around the world, just in the last five years, 85 percent of people have already made lifestyle changes in the name of sustainability.

Inventor

Mark H. Costello

CEO/COO/ Plant Managers

4/6/2025: Prototype is coming soon! Please E-Mail me if you are interested in being notified.

Frequently Asked Questions

How did you come up with your idea?

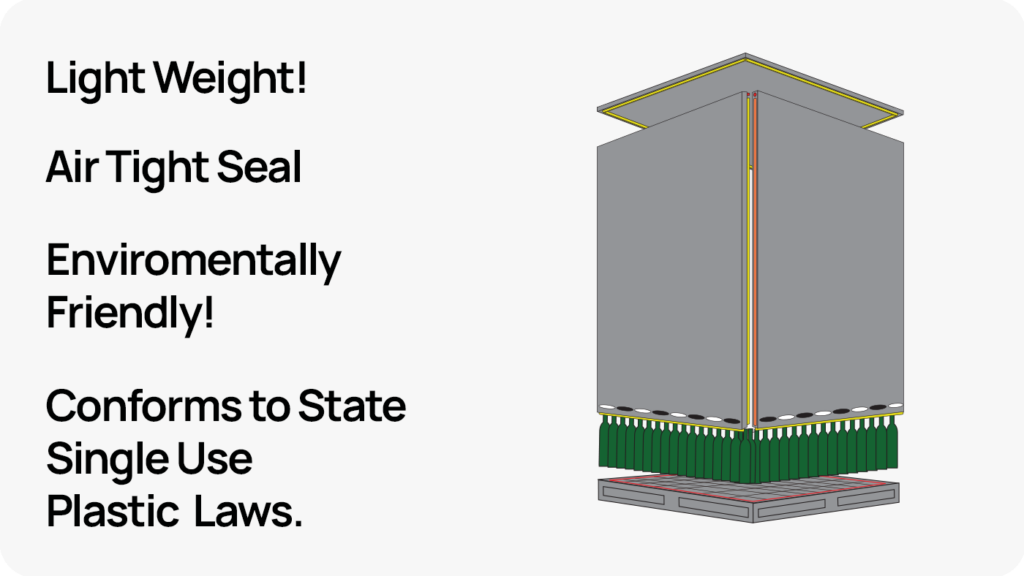

As I was servicing a production line for a winery several years ago, I couldn’t help but notice the massive amount of plastic we were throwing away within an eight hour period. I thought to myself “can a crate be designed for the transfer of bulk glass?” I then through trial and error designed and patented a pallet, panel and cap system that would protect its contents as well or better than stretch wrap.

Do you want to License or sell your patent?

It would really depend on the offer. I am fifty eight years old, so a buyout would definitely not be out of the question.

Describe modifications customers will need to accept your panel system.

When the glass stack is in position for panel removal, a suction device will lift the lid so that each panel may be removed by another suction or hook device. The tech will then place all four panels onto a pallet. He or she will then release suction so the lid can sit back on top of the stack. The stack will now move down to the bottle staging station where a robot arm will remove the lid and stack it on a pallet. Now the bottles can be pushed layer by layer onto the production line.

How are the panels placed on the stack at the glass plant.s plant?

Robotically.

How important is it for glass plants to consider switching over to your system?

The amount of plastic glass plants create is phenomenal. Scroll back up and take a look.