|

ASSEMBLY(1) -

ASSEMBLY

(2) -

RESTRAINT SYSTEM -

WASTE CALCULATIONS -

PRESS RELEASE LETTER FROM THE INVENTOR - LICENSING - CONTACT - TERMS - COMPARISON - SITE MAP |

|||||

|

|||||

|

|

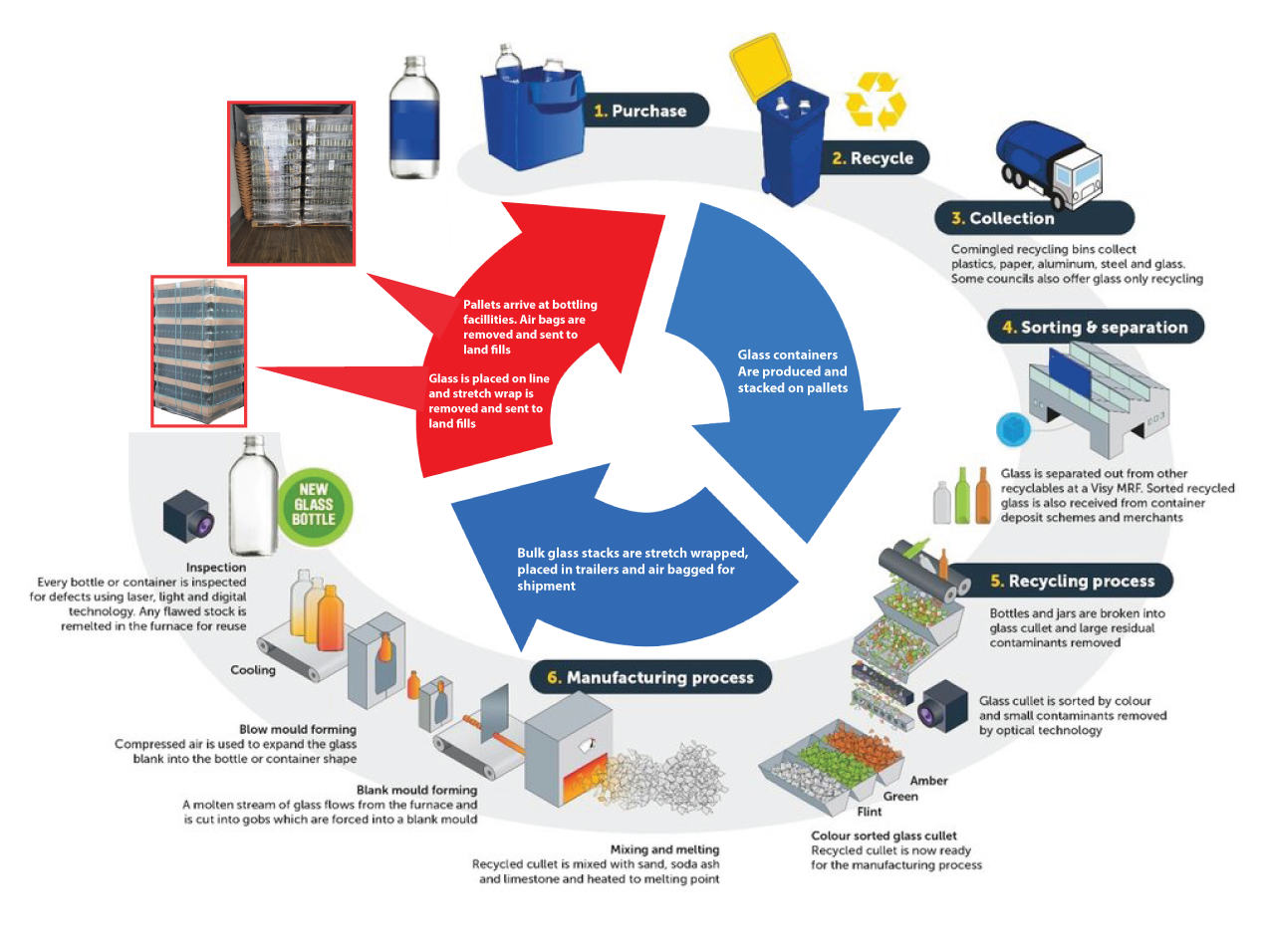

Did you know that after glass bottles are produced, they are stacked on pallets and stretch wrapped, and then loaded into trailers where approximately five to eleven air bags are used to stabilize the load? All of this plastic gets thrown away by their customers like breweries, wineries and food processing plants. Pictured below on the left is a standard stack of bulk glass. Pictured on the right is my patented restraint system.

New Patented Method |

||||

|

|

|||||

|

|

|||||

|

Illustrated in the graphic below are the standard steps taken by glass plants to ensure glass is recycled in a responsible manner. The red arrow indicates the manufacturing behaviors that need to change so they can close the loop on their production process. |

|||||

|

|

|||||

|

STANDARD SHIPPING METHOD DOES NOT FALL IN WITH ENVIRONMENTAL REGULATIONS RELATED TO SB54 STRETCH WRAP IS SENT TO OTHER COUNTRIES OR DUMPED INTO LAND FILLS.

"A

closed-loop supply chain uses reverse logistics to feed products that

have served their purpose back into the logistics process.

CLOSED LOOP SHIPPING METHOD 100% RECYCLABLE ADHERES TO SB54 ENVIRONMENTAL LAW ADHERES TO THE CLOSED LOOP SUPPLY CHAIN METHOD |

|||||

|

HOME -

ASSEMBLY(1) -

ASSEMBLY

(2) -

RESTRAINT SYSTEM -

WASTE CALCULATIONS -

PRESS RELEASE |

|||||